T2150 Mashiinka Dalxiiska Dalxiiska Gaarka ah ee Matoorka Dabaysha Tamarta

Dabeecadda mashiinka

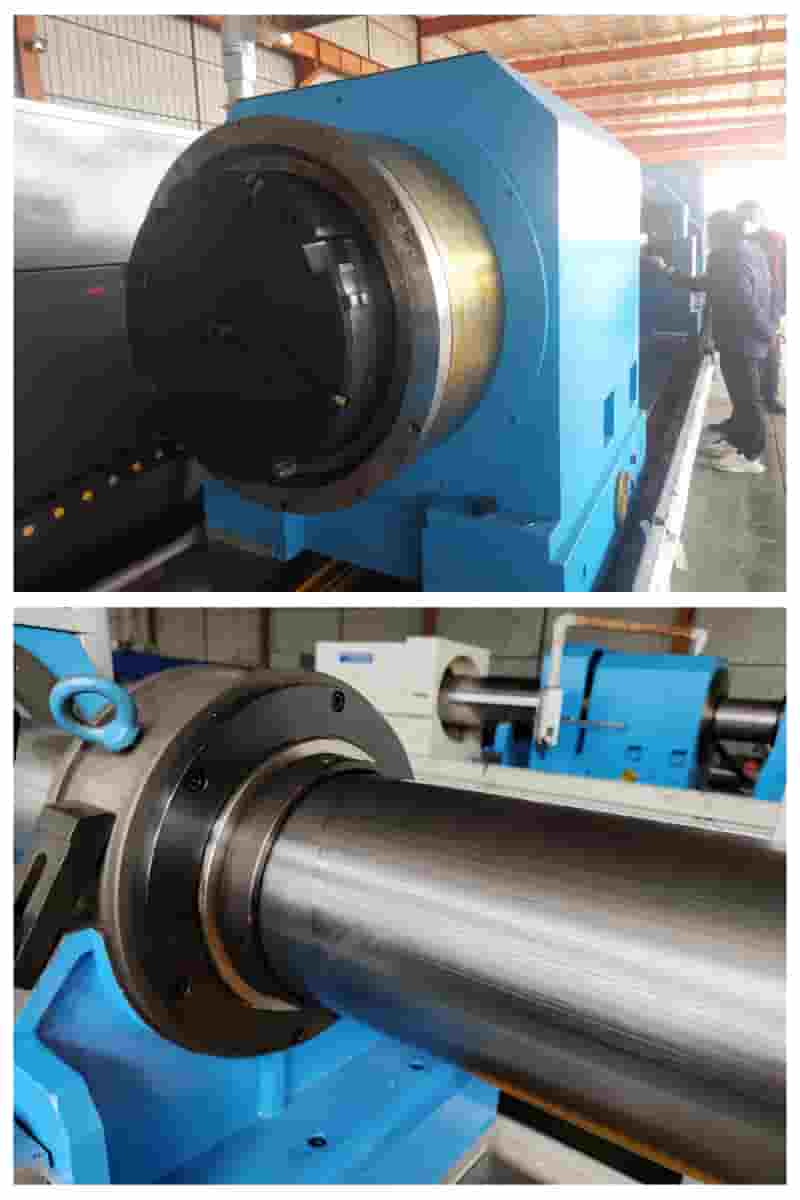

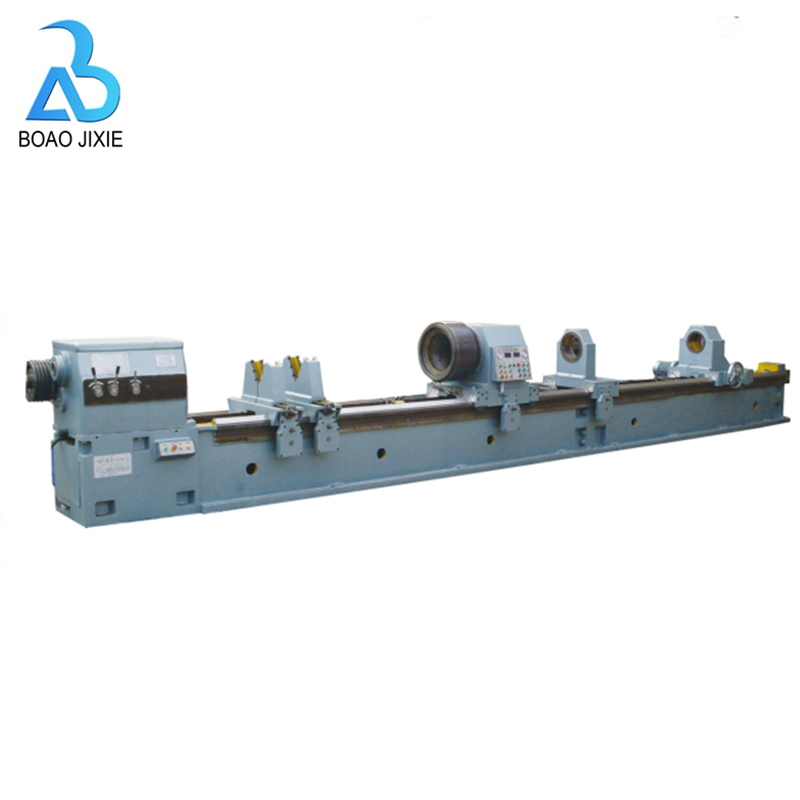

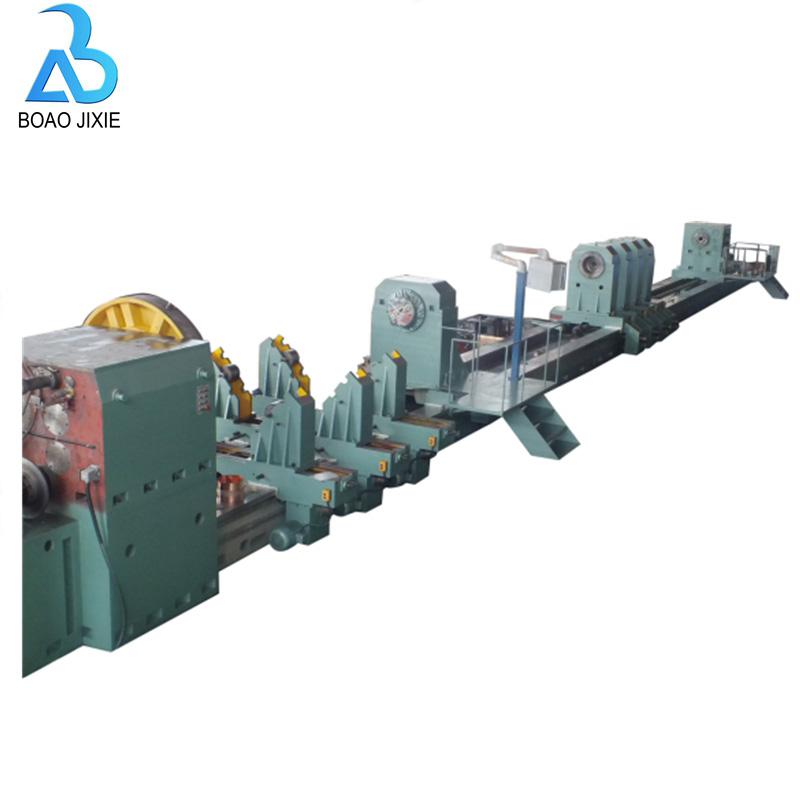

Qodista godka qoto dheer ee T2150 iyo mishiinka caajiska ah waa qalab culus oo taxane ah oo godad qoto dheer leh oo ay soo saartay shirkadeena iyadoo loo eegayo sifooyinka farsamaynta ee qalabka isdifaaca tamarta dabaysha hadda iyo baahida suuqa.Qalabka mashiinka laftiisa ayaa leh qallafsanaan xooggan wuxuuna ilaaliyaa saxnaanta wanaagsan.Spindle-ku waxa uu qaataa nidaaminta xawaaraha saddex-xawaaraha ee tallaabo-la'aanta (sare, madhan, hooseeya), iyo kala duwanaanta xawaaruhu waa ballaadhan yahay.Nidaamka quudinta waxaa wada matoor awood sare leh oo AC servo ah, kaas oo dabooli kara baahida hababka kala duwan ee habka daloolka qoto dheer..Saliideeyaha waxaa loo isticmaalaa in lagu adkeeyo qalabka shaqada ee qalabka farsamada, kaas oo ammaan ah oo la isku halleyn karo.Qalabka mishiinku wuxuu dhamaystiri karaa qodista, caajiska, fidinta iyo rogrogista ee qaybaha godka qoto dheer ee dhererka culus.Inta lagu jiro farsamaynta, workpiece-ku wuxuu ku wareegaa xawaare hooseeya, qalabkuna wuu wareegtaa oo wuxuu ku quudiyaa xawaare sare.Markaad qodayso, qaado habka tignoolajiyada ee ka saarista chip ee BTA;Markaad caajisto, qaado habka tignoolajiyada ee bixinta dareeraha goynta ee baarka caajiska ah iyo sii daynta dheecaanka goynta iyo feylasha birta ee hore (dhammaadka madaxa);marka loo eego baahida farsamaynta, qalabka mishiinku waxa uu ku qalabaysan yahay sanduuqa ul daloolka, qalabku waa la wareejin karaa oo la quudin karaa.Qalabka mashiinka inta badan waxaa ka mid ah sariirta, sanduuqa sariirta sariirta, sanduuqa tuubada daloolka, quudiyaha saliidda, nidaamka quudinta, xargaha xarunta shaqada, bracket workpiece, taageerada bar caajisnimada, qaadista quudinta, nidaamka qaboojinta (oo leh qalabka saarista chip), nidaamka hydraulic.Qalabka mashiinkaani wuxuu si dabacsanaan ah u dooran karaa habka farsamaynta iyadoo loo eegayo baahiyaha dhabta ah, wuxuuna leeyahay codsiyo badan oo kala duwan.

| NO | Walxaha | Sharaxaada |

| 1 | Taxanaha nooca mashiinka | T2150 |

| 2 | Dhexroorka qodista ayaa dhacay | Φ30-120mm |

| 3 | Dhexroor caajis ah ayaa garaacay | Φ220-500mm |

| 4 | Moolka caajiska ah | 1-12m |

| 5 | Kala duwanaanshaha isku dhejinta dhejiska | Φ1600mm |

| 6 | Dhererka dhexda dunta mashiinka | 900mm |

| 7 | Xawaaraha dunta madaxa | 1-225 r/m, 3 gears, tallaabo la'aan |

| 8 | Dhexroor daloolka lafdhabarta | Φ130mm |

| 9 | Dhexroor dalool taper dunta hore | 140 # |

| 10 | dhexroor dalool dunsan sanduuqa bar caajis | Φ120 |

| 11 | Boring bar sanduuqa dunta dunta hore god taper | 140#, 1:20 |

| 12 | Xawaaraha santuuqa bar caajiska ah | 20-400 rpm, 6 caleemo |

| 13 | Xawaaraha dhaqaaqa degdega ah ee pallet | 2m/daqiiqo |

| 14 | Xawaaraha quudinta | 5-1000mm/daqiiqo, tallaabo la'aan |

| 15 | Matoorka ugu muhiimsan | 45 kw |

| 16 | Matoorka bar caajis ah | 22KW |

| 17 | Quudi awoodda matoorka | 1.5kw |

| 18 | Quudinta gaadhiga awood degdeg ah | 5.5KW |

| 19 | Matoorka bamka qaboojiyaha | N=5.5kw (3 kooxood) |

| 20 | Cadaadis lagu qiimeeyay nidaamka qaboojiyaha | 2.5Mpa |

| 21 | socodka nidaamka qaboojinta | 100,200,500 L/daqiiqo |

| 22 | Nidaamka qaboojiyaha ayaa lagu qiimeeyay cadaadiska | 6.3 Mpa |

| 23 | Culayska ugu badan ee xoogga dhidibka | 6.3 Kn |

| 24 | Max oiler hagaajinta xoogga for workpiece | 20KN |

| 25 | Culayska ugu badan ee mashiinka | 20T |

| 26 | Nidaamka xakamaynta | Siemens 808 ama KND |

Qaybaha Mashiinka ee Muhiimka ah